How To Adjust Pressure Relief Valve

How to adjust pressure relief valve. Pressure relief valves play a vital role in maintaining the safety and functionality of different systems, including hydraulic systems, steam boilers, and weight vessels. These valves are designed to discharge excess weight in a controlled way, avoiding catastrophic failures and ensuring the judgment of the system.

Adjusting a weight relief valve may be a basic task that requires exactness and adherence to specific guidelines. We’ll take you step-by-step through the process of changing pressure relief valves in this extensive tutorial, which also covers important ideas, safety measures, and useful advice.

The basics of How to adjust pressure relief valve

Basic Components

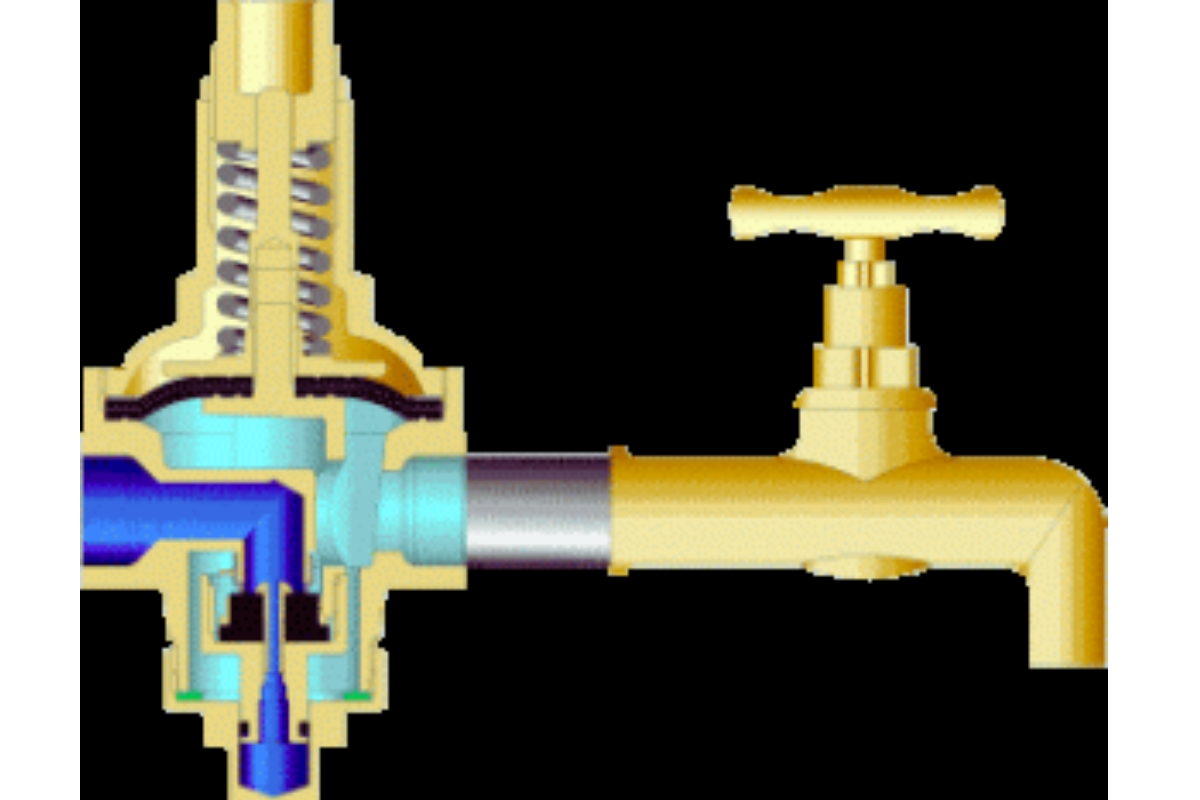

Pressure relief valves typically comprise a valve body, a spring, a circle, and an adjustment component. The valve is held closed by the spring constraint against the system weight. When the pressure exceeds the set point, the valve opens, allowing excess liquid to escape.

Types of Pressure Relief Valves

There are different types of weight relief valves, including direct spring-loaded, pilot-operated, and adjusted bellows help valves. Each type has its own unique characteristics and applications.

Setting Pressure

The pressure at which the relief valve opens is known as the set point. It is usually a crucial parameter that must be carefully decided based on the system requirements and the valve’s specifications.

Safety Precautions

Before attempting to adjust a pressure relief valve, it is fundamental to prioritize safety to prevent accidents and injuries.

Equipment Inspection

Inspect the pressure relief valve and related hardware for signs of wear, erosion, or damage. Replace any faulty components before proceeding.

System Shutdown

Ensure that the system is safely closed down before attempting to adjust the weight relief valve. This may include isolating the valve from the pressure source and depressurizing the system.

Personal Protective Equipment (PPE)

Wear appropriate PPE, including safety glasses and gloves, to protect against potential hazards.

Step-by-Step Guide to Adjusting Pressure Relief Valves

Identify the Set Point

Determine the desired set point for the pressure relief valve based on system prerequisites and producer recommendations.

Access the Adjustment Mechanism

Locate the adjustment component on the weight relief valve. This may include removing a protective cap or cover.

Use Proper Tools

Utilize the appropriate devices, such as a wrench or screwdriver, to make alterations. Refer to the valve’s technical documentation for particular instrument requirements.

Turn the Adjusting Screw

Gradually turn the adjusting screw in the indicated direction to increase or decrease the spring tension. This, in turn, adjusts the set point of the weight relief valve.

Monitor Pressure

While adjusting, screen the system weight closely using pressure gauges. Make incremental adjustments and observe the impacts on pressure to achieve the desired set point.

Lock in Position

Once the right set point is achieved, secure the adjustment component to avoid unintentional changes. This may include tightening a lock nut or using a locking device.

Testing and Validation

Perform System Checks

After adjusting the weight relief valve, perform a comprehensive system check to ensure legitimate functionality.

Leak Detection

Check for any spills around the pressure relief valve and related connections. Address and rectify any issues promptly.

Verify Set Point

Validate that the weight relief valve opens at the intended set point by conducting controlled weight tests.

Maintenance and Periodic Inspections

Establish a Maintenance Schedule

Establish a routine maintenance program for weight relief valves. This covers functional testing, visual inspections, and any necessary alterations.

Record Keeping

Keep thorough records of all maintenance activities, weight assistance valve changes, and inspections. For monitoring the valve’s performance over time, this data is crucial.

Common Challenges and Troubleshooting

Valve Sticking

If the weight relief valve is stuck or not working easily, it may require cleaning or lubrication. Follow the manufacturer’s rules for maintenance.

Inaccurate Set Point

If the pressure relief valve is not coming to the desired set point, reevaluate the adjustment and consider factors such as spring wear or system changes.

Excessive Leakage

Excessive leakage during operation may show a damaged structure or seal. Inspect and replace these components as needed.

Conclusion

Although it may seem like a simple process, adjusting pressure relief valves involves strict attention to detail and respect to safety procedures. The safe and dependable operation of pressure relief valves depends on routine maintenance, sporadic inspections, and a deep comprehension of the system’s requirements. Operators can improve workplace safety and preserve the integrity of their systems by adhering to the guidelines provided in this thorough manual. When in doubt, don’t hesitate to seek advice from the valve manufacturer or another authorized expert.